Your cart is currently empty

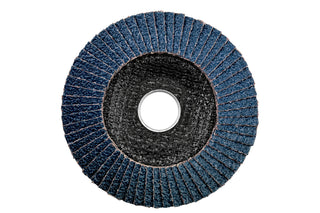

Klingspor 115mm z40 Flap Disc (10 Pack) Abrasive mop disc for stainless steel and steel

The abrasive mop disc has been designed for universal edges and surface work and is used on such materials as:

- stainless steel

- steel.

The abrasive stands out with its excellent removal rate and is held in equally high regard by professional users and do-it-yourselfers. Anyone attaching prime importance to finishing their work swiftly and with excellent results will benefit during their daily routine from the exceptional qualities of the abrasive mop disc is convex shape. This shape allows for high aggression due to the small contact area. It is, therefore, ideal for work on edges and for grinding weld seams.

Superior abrasive performance thanks to zirconia alumina

The grain chosen for this product is tried-and-tested zirconia alumina. The disc is made up of a high-quality glass fibre backing plate that is extremely durable. The disc is extremely effective with low power angle grinders. The disc will not glaze even if used at a low grinding pressure. The result is significantly improved handling combined with outstanding results and surface finishes of exquisite quality.

Abrasive mop disc with an ideal price-performance ratio

The abrasive mop discs Klingspor offers in this product line combine suitability for universal use with a high level of aggressiveness and long service life at the best possible price-performance ratio. This universal product produces its best results on various materials including steel. The abrasives grouped in the Extra product line are the natural choice for anyone who wishes to enjoy a high removal rate without having to pay a premium price. . In addition to convex mop discs, such as the product presented here, Klingspor also offers mop discs in a flat design for surface grinding.

The benefits at a glance

Optimised performance

The abrasives used have also been engineered to work with high-speed angle grinders (80 m/s) and are designed to offer a wide range of possible applications. The optimised arrangement of the grinding flaps ensures first-rate grinding performance, long service lives and optimised utilisation to the end.

Sustained high performance

The cloth flaps are coated with zirconia alumina, ceramic or aluminium oxide and spaced equally on the backing plate. The optimised cloth-reinforced backing guarantees the operator a fresh grit and, thus, consistent removal throughout the entire work process.

Extraordinary stability

The backing plates included in our SMT range are made of glass fibre or glass-fibre reinforced plastic. They are extremely hard-wearing and deliver optimal power transmission to the work piece.

Tried-and-tested safety

A special manufacturing process ensures an exceptionally strong bond between baking plate and grinding flaps and produces a level of break resistance that easily exceeds the provisions of the oSa and EN 13743 standards.

Applications

- Metals

- Steel

- Stainless steel

- High-alloy stainless steels

- NF metals

- Aluminium

- Paint

- Varnish

- Plastics

- Wood